Jay Greene from CNET has published a great article about the REE, what they are used for and the state of the Rare Earth industry addressing very important environmental concerns. Modern technology and, particularly, Mobile and New Energy Applications like Wind, Solar and Electric Cars can not be produced without REE. Safe way of production means that the prices will go up and Security of Supply of These Strategic Commodities will be driving investment demand here.

The rare-earth mineral mine in Mountain Pass, Calif., run by Molycorp.

(Credit: Jay Greene/CNET )

MOUNTAIN PASS, Calif. -- About 60 miles southwest of Las Vegas, in a mine some 500 feet deep, the beginnings of an

iPhone come to life.

But the sleek, shiny iPhone is far, far removed from the rocks pulled out of this giant hole, which looks like a deep crater on the moon. A very deep crater. The ground is covered with rust-colored boulders, rocks, and pebbles. The walls etched with striations in varying shades of black, are notched, every 75 feet or so, creating steps that only a giant could use to climb out of the pit.

The base of the mine is several football fields wide. Massive yellow excavators pull huge clumps of dirt from the earth, depositing them into equally giant haulers. And on this baking hot July day, when the temperatures approach 100 degrees, a geyser of water is shooting from a truck, in a never-ending bid to tamp down the dust.

Inside the rocks from this mine are rare-earth minerals, crucial ingredients for iPhones, as well as wind turbines, hybrid

cars, and night-vision goggles. Minerals such as neodymium are used in magnets that make speakers vibrate to create sound. Europium is a phosphor that creates a bright red on an iPhone screen. Cerium gets put into a solvent that workers use to polish devices as they move along the assembly line.

"Your iPhone doesn't work without rare earths in there, " said Mark Smith, chief executive of Molycorp.

What's unique about Molycorp is that it's trying to harvest rare-earth minerals in an environmentally friendly way, or at least as environmentally friendly a way as a mine can manage. The company has come up with a proprietary method that it believes is the answer to the toxic mess that's defined much of the world's rare-earth mining. And if Molycorp executives are correct, they may be modernizing rare-earth mining in a way that could force Chinese competitors to improve the way they operate.

"We started working at trying to do things differently," Smith said during a tour of the mine.

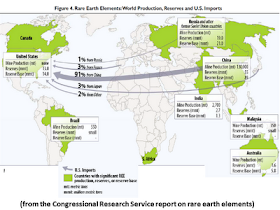

That's important, because in China, which produces more than 90 percent of the world's supply of rare-earth minerals, environmental laws have historically been scant and enforcement lax. The center of rare-earth mining there is Baotou, a city in Inner Mongolia with 2.3 million residents that's become something of a poster child for mining's ecological wreckage.

By some accounts, the smog in Baotou can be dense, the air acrid. But the biggest hazard is an artificial "tailings" lake west of the city, where refineries that process the rare-earth minerals dump their waste. A Daily Mail reporter, who sneaked past guards and climbed sand dunes to reach the rim of the lake, described it as "

an apocalyptic sight."

"The lake instantly assaults your senses. Stand on the black crust for just seconds and your eyes water and a powerful, acrid stench fills your lungs," the article read.

Chinese state media reported that a 2006 study by local authorities showed levels of radioactive thorium in soil near the lake were 36 times higher than other areas of Baotou. Thorium is typically found in the same ore as rare-earth minerals and separated out during processing. Exposure to high levels of thorium can cause lung and pancreatic cancer.

A satellite image of the rare-earth mineral tailings lake in Baotou, China.

(Credit: GeoEye Satellite Imagery )

Molycorp's Smith believes his company can rewrite the way vital rare-earth minerals are mined and processed. Molycorp machines are now pulling some 2,800 tons of fresh ore from the ground in Mountain Pass per day, four days a week. Those rocks are hauled to a massive crushing facility, a warren of tubes and conveyer belts that ultimately lead to a silo where the ore gets pounded into pieces about three-eighths of inch wide.

1-2 of 9

Scroll LeftScroll Right

Those pebbles then move via conveyer belt to a mill, a long rectangular building, high on a plain overlooking the Mountain Pass site. There, they get mixed with water and dumped into a giant cylinder with large steel balls. The mixture turns into a slurry that moves to a so-called hot floatation facility.

Molycorp adds chemicals to the mix that, when heated, cling to the rare-earth minerals and rise with the bubbles that float to the top. The company then skims off the rare-earth concentrate.

The remainder, about 92 percent of the entire mix, has no commercial value. In Baotou, that mix, which includes slightly radioactive thorium and uranium and other toxic chemicals, goes into the tailings lake. Because it's still liquid, the waste can leach into groundwater, creating environmental hazards. Molycorp's proprietary process presses the water out of the tailings in order to reuse it. What's left is a paste, to which Molycorp adds cement and then lays out in a lined disposal site.

"One thing you won't see at Mountain Pass is a pond of radioactive waste," Molycorp's Smith said. "No tailings pond, no worries about contaminated groundwater."

(The story continues below. Click on the image to download the infographic.)

(Credit: Mark Hobbs/CNET )

(Credit: Mark Hobbs/CNET )

The rare-earth concentrate heads to a separations facility, where acids are added to pull apart the different rare-earth minerals. Eventually, the separate elements are dried, and the powder versions of neodymium, europium, and the rest are bagged up and sold to customers, some of them Apple's partners that make the speakers, the screen, and the vibration unit that comprise an iPhone.

"We are well indoctrinated into that iPhone," Smith said. "We're an important and indispensable part of that iPhone."

You get the sense walking around Mountain Pass with Smith, even in his oh-so-out-of-place business suit and tie, that there's no place he'd rather be. Square-jawed and sporting a crew cut, Smith says he could talk about rare-earth minerals all day. He mentions dinners with his wife, when he points to all the different objects in the restaurant that wouldn't exist without rare-earth minerals (which makes me think Mrs. Smith is an awfully tolerant woman).

Molycorp Chief Executive Mark Smith

(Credit: Jay Greene/CNET )

Smith, a lawyer with a degree in agricultural engineering from Colorado State University, wants to rewrite the global rare-earth mining playbook. He believes Molycorp, which invested $895 million to modernize the mining operations here, could seize as much as a third of the global market for rare-earth minerals when the revamped Mountain Pass facility becomes fully operational next year.

Can Molycorp compete with its Chinese rivals? Jack Lifton, founding principal at the mining research firm Technology Metals Research, notes that China has developed "a technically sophisticated rare-earth processing industry and a strong academic community in the rare-earth chemistry and processing fields." While the Chinese don't elaborate on their costs, Lifton is dismissive about any claims that Molycorp can significantly undermine rivals' costs.

The Chinese government has also increased efforts to reduce the ecological damage of rare-earth mining. It's instituted quotas and restricted exports of the minerals in recent years, in part because the government has ramped up environmental oversight, though many suspect the move was also intended to drive up prices.

"There are a lot of things that the rare-earth industry should not be proud of over there," Molycorp's Smith said about the environmental mess in China. "But I'll give China credit. They are stepping up their environmental regulation." The Chinese government recently released

a report detailing some of those environmental efforts, including new laws focused on water pollution and treatment and plans to enforce them.

There's little doubt the environmental cost of creating an iPhone, as well as those wind turbines, hybrid engines, and the bevy of other technical wonders that use rare-earth minerals, has been immense.

But regulatory pressure, coupled perhaps with the market forces of the new Molycorp mine, could be the start of a cleaner rare-earth mining industry."